Rotary Rebar Bender verses Three Point Rebar Bender

There are two basic methods for bending rebar. Each method has its pluses and minuses. Knowing the differences can help you make the best purchasing decision. Let’s take a look at each one in more detail.

A rotary rebar bender has a disk in the middle that turns. Different sizes of bending dies are placed in the center of this disk depending on the bending radius you want. A post located on the disk grabs the rebar and bends it around the bending die. Lastly there is a support roller to hold the bar where it is being fed in.

The amount that the rotating disk turns will determine how many degrees the rebar is bent. There are different ways to control this rotation. The simplest is a lever that, when moved back and forth, positions a limit switch that will determine how much the disk will rotate before it stops and returns back to the starting point. The lever has stops so you can lock the position once you are getting the bend angle you want. Two stops allow you to easily make shapes that have two different angles. An example would be a seismic stirrup. Seismic stirrups have three 90 degree bends and two 135 degree bends.

The most advanced (and more expensive) method is to control the disk rotation with a programmable angle controller. A rotary encoder on the shaft of the rotating disk senses its position with pinpoint accuracy and relays that information to the controller. Most controllers are able to store a number of angles into memory and will automatically sequence through them as you are forming your shape on the rebar bender.

When bending rebar on a rotary rebar bender, one side of the bar remains stationary. This makes it easier to bend a hook on the end of a 20 foot long bar especially when you are working with heavy bars that are larger than #5 or #6 rebar. You can also make a full 180 degree hook in one continuous motion. Most 3 point benders can bend up to around 135 degrees.

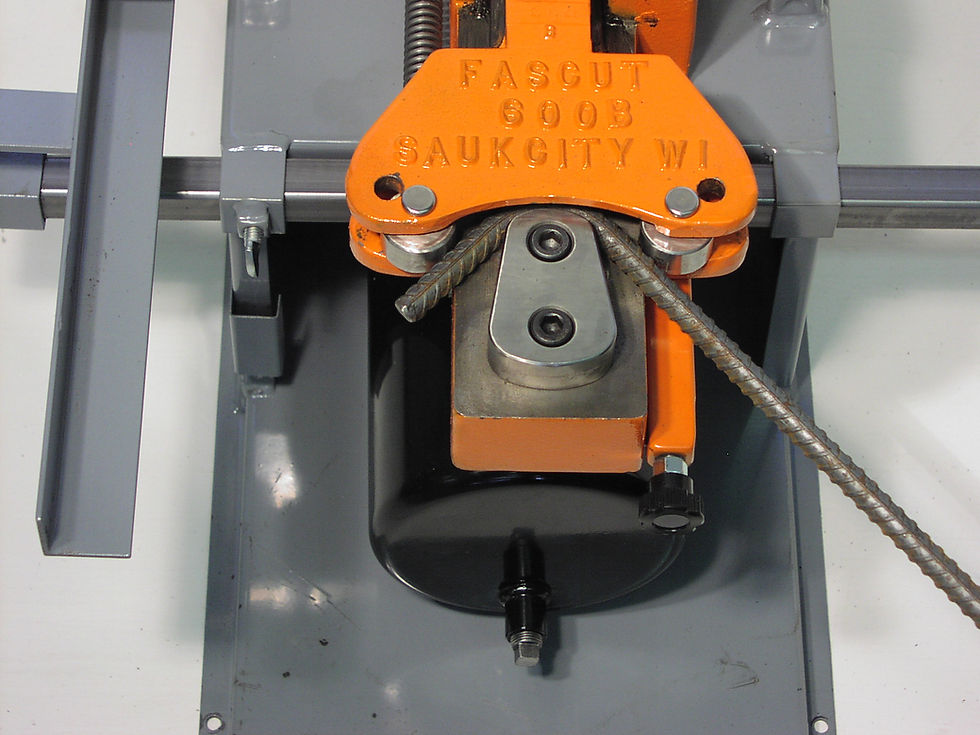

A three point rebar bender usually has two bending rollers mounted on a ram that pushes forward against a stationary bending die. The mechanics needed to produce this motion is a lot simpler and less complicated when compared with the turning disk on a rotary rebar bender. A smaller, lighter and more portable rebar bender is the result.

The more the ram pushes forward, the more bend angle is applied to the rebar. An adjustable angle control triggers a limit switch causing the ram to stop and go back to the starting point. Once set, all bends will have exactly the same angle. A shape that has two different bend angles like a seismic stirrup can be made in two steps. After cutting rebar to the necessary length, set the angle to 135 degrees and bend both ends of the rebar. Do this for as many as you need and then reset the angle to 90 degrees to finish bending the seismic stirrups.

When you add a rebar cutter to a rotary rebar bender or three point rebar bender you now have a multipurpose combination machine that can both cut and bend rebar at your shop or taken out to the jobsite.

Factors to consider when deciding which model to choose are: maximum capacity, size, weight, power requirements, and bending type.